Custom metal forming, shaping and bending is a key component in the precision metal manufacturing proces, perfectly complementing our design and precision engineering, laser cutting, welding and fabrication, metal finishing and product assembly services.

Our in-house we have Four Forming Machines, with various capacity, with a maximum force up to 320 tons and a maximum length 4m, we are able to satisfied our customers needs.

Using lean manufacturing and 5s techniques here at our metal forming and manufacturing facility, we not only ensure top quality but also productivity advantages for our clients including faster turnaround and cost-efficiencies with our custom metal forming. We can manufacture large quantities to order with high precision, producing the final form to your requirements.

Coupled with a high level of expertise, our metal shaping and metal banding tools and processes also guarantee quality, accuracy and excellent performance, ensuring that we offer you high quality parts or components through to fully finished products each and every time.

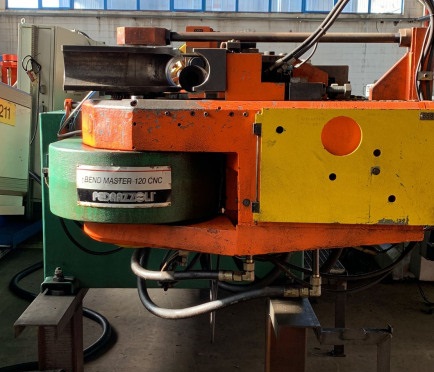

In addition to sheet metal forming, we also offer tube forming and sheet metal bending services to enhance our production capabilities. In partnership with a selection of trusted suppliers we can offer a wide variety of production techniques to supply parts quickly and competitively.

In addition to Sheet Metal Forming, we also offer Tube Bending and Sheet Metal Rolling services to enhance our production capabilities. In partnership with a selection of trusted suppliers we can offer a wide variety of production techniques to supply parts quickly and competitively.